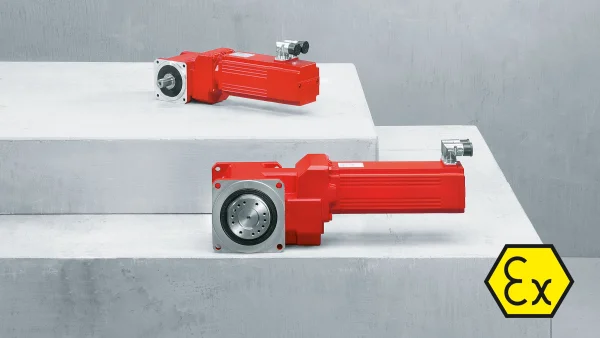

The explosion-proof helical-bevel servo gearmotors provide maximum operational safety. Specially designed for achieving high performance in precise processes, they are fully scalable and offer short response times.

Optimum explosion-proof gearmotors

Force, precision, and safety come together to form a true unit in our explosion-proof BS.F..CMP.. helical-bevel servo gearmotors. Thanks to their compact design in the form of helical-bevel servo gearmotors, they offer you optimum mounting options and a wide variety of possible applications.

This is particularly relevant for potentially explosive areas where dust and gas emissions are a safety issue. Rotational clearances remain constantly low throughout the entire service life of this servo drive due to the high-endurance design of the running gears.

Take advantage of our large selection of gear unit-motor combinations for a wide range of applications that require high torques and precise performance. These combinations are also suitable for complex automation tasks in which several processes are merged to form an overarching process.

By using our explosion-proof helical-bevel servo gearmotors, you will obtain a high level of process reliability, efficiency, and cost effectiveness. The explosion-proof BS.F.. servo gearmotors are extremely robust and low-maintenance thanks to their high-quality manufacturing and precise tooth elements. This makes them even more efficient when combined with our CMP.. synchronous servomotors that can be precisely controlled.

Certification according to ATEX includes equipment group II and equipment category 3. The combinations are available in II3GD and II3D design.

Get in touch with us.

Your benefits

-

Ensure safety

Explosion-proof helical-bevel servo gearmotors provide protection for equipment group II and categories 2 and 3. -

Achieve high performance

Explosion-proof BS.F..CMP helical-bevel servo gearmotors impress with their power, precision, and compact design.

Features

Explosion-proof helical-bevel servo gear units

BS.F series

- Gear units comply with Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX), equipment group II, equipment category 2, II2GD design

- Certified protection types:

- Protection type “c”: Protected by safe construction (design safety), EN13463-1 and -5

- Protection type “k”: Protected by liquid immersion, EN13463-1 and -8

- All screws are secured against automatic loosening

- Gear unit has a separate nameplate

- High-quality oil seals

- Lubricant can withstand high temperatures

- Low-backlash ATEX-compliant helical-bevel servo gear units

- Designed for torques from 40 Nm to 1220 Nm

- All variants come with a B5 mounting flange with optional foot mounting and torque arm (can be integrated into the relevant application)

- The rotational clearance remains constant over the entire gear unit service life

- Available in three output variants:

- BSF: Solid shaft

- BSKF: Solid shaft with key

- BSAF: Hollow shaft with key (shaft-mounted gear unit)

- In a servo gearmotor version with ATEX compliance

Explosion-proof synchronous servomotors

CMP.. series

- Compliant with Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX), equipment group II, equipment category 3

- Category II 3GD, for use in zones 2 / 22

- Category II 3D, for use in zone 22

- Also available with brake and Hiperface® encoder (with electronic nameplate) in Category 3D

Technical data

BS.F..CMP.. gearmotors

| BS.F.. gear units | CMP.. motors |

|

|---|---|---|

| Gear unit size | Size | Torque range MaDyn Nm |

| 202 | 50S – 63S |

15 – 60 |

| 302 |

50S – 71M |

20 – 120 |

| 402 |

50S – 100S |

29 – 225 |

| 502 |

63S – 100S |

63 – 385 |

| 602 |

63M – 100L |

114 – 800 |

| 802 | 71M – 100L | 230 – 1680 |

Areas of application

| Product | Design | Zone |

|---|---|---|

| Gearmotor (directly mounted gearmotor) | II3GD II3D |

2/22 |

| Stand-alone gear units (gear units with adapter AQ) | II2GD | 1/21 2/22 |

| Stand-alone CMP.. motor | II3GD II3D |

2/22 22 |

Example:

- Load-bearing devices in stacker cranes

- Handling gantries

- Cycle feeds

- Tire, rubber and plastic processing machines

- Conveyor belts

- Travel axes, additional axes

- Cutting, punching, welding and embossing films, wood or plastic